You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building Materials Old & New

- Thread starter Arlington

- Start date

- Joined

- Dec 10, 2011

- Messages

- 5,599

- Reaction score

- 2,717

Before stone gravel could be made (crushed) cheaply, what did they use?

The material under my c. 1920 sidewalk looks more like gas grill "lava rocks" (black, granular, and lightweight). It looks nothing like highway or concrete or RR ballast gravel--too easily crumbles.

Is it some kind of coal or steelmaking waste that would have been cheap and abundant in 1920?

The material under my c. 1920 sidewalk looks more like gas grill "lava rocks" (black, granular, and lightweight). It looks nothing like highway or concrete or RR ballast gravel--too easily crumbles.

Is it some kind of coal or steelmaking waste that would have been cheap and abundant in 1920?

Last edited:

F-Line to Dudley

Senior Member

- Joined

- Nov 2, 2010

- Messages

- 9,561

- Reaction score

- 10,462

Before stone gravel could be made (crushed) cheaply, what did they use?

The material under my c. 1920 sidewalk looks more like gas grill "lava rocks" (black, granular, and lightweight). It looks nothing like highway or concrete or RR ballast gravel--too easily crumbles.

Is it some kind of coal or steelmaking waste that would have been cheap and abundant in 1920?

Coal cinders. Pre-WWII railroads also used a lot of that for track ballast in lieu of modern crushed stone, in part because they could use their own industry supply chain to make and spread the stuff. Usually mixed with coarse sand. You still find lots of cinder ballast on active but minimally-maintained freight branchlines throughout the region.

- Joined

- Dec 10, 2011

- Messages

- 5,599

- Reaction score

- 2,717

Awesome, @F-Line to Dudley , am I correct in guessing that coal cinders faded sometime in the late 50s or early 60s, during the generational turnover to oil and gas as industrial fuel (in this case, not just that the RRs switched to diesel, but everybody did), and at the same time industrial rock crushing emerged to serve concrete and interstate highway construction?

Here's a photo, BTW:

Here's a photo, BTW:

Last edited:

F-Line to Dudley

Senior Member

- Joined

- Nov 2, 2010

- Messages

- 9,561

- Reaction score

- 10,462

Awesome, @F-Line to Dudley , am I correct in guessing that coal cinders faded sometime in the late 50s or early 60s, during the generational turnover to oil and gas as industrial fuel (in this case, not just that the RRs switched to diesel, but everybody did), and at the same time industrial rock crushing emerged to serve concrete and interstate highway construction?

Here's a photo, BTW:

View attachment 9410

Probably a little earlier. Domestic dieselization began on a large scale during the late-30's...was paused for Wartime as all new tech was rationed to war applications...then re-accelerated greatly from the mid-40's there until steam was basically defunct nationwide by '55. Same goes for industry applications where stream turbines were rapidly replaced by diesel at the same pace to the same general '55-ish end date. Since building materials of all kinds were heavily rationed for the War effort, there's probably a hard maintenance cutoff for municipal and RR coal cinder use of circa-1940 when the supply chain started being heavily diverted. And then it simply never came back, as any postwar burst of state-of-repair catchup and first kickoffs for the decades-long redev boom would've immediately started using New England-mined trap rock abundantly sourced from local quarries. A lot of those quarries (esp. prevalent in Connecticut) multiplied in number during the War and/or massively re-mechanized themselves. So by the time wartime materials controls were relaxed the trap rock quarries simply maintained their breakneck production levels and 1:1 took over for coal cinders rather than there being any last-gasp burst on the supply chain sourced from the terminally dying coal/steam industry.

I've got some old "Geology of Connecticut"* glossy color book I received as a gift a while ago that details some of the history of the trap rock mining industry there and that wartime era when it really blew up as the #1 source of paving stone throughout the Northeast/Mid-Atlantic/Great Lakes regions.

EDIT*:

Bell, The Face of Connecticut: People, Geology, and the Land, 2nd Printing. State Geological and Natural History Survey of Connecticut, ©1985.

Found in a used bookstore in Eureka, CA of all bizarre places by a friend of mine. Publication of the State Geological Survey, division of the CT DEPA (copyright page has the Governor, DEPA Commissioner, and Chief State Geologist on the Editorial masthead). Full of absolutely gorgeous color plates with photos & guided illustrations of the state's geological history corner-to-corner, along with almost 200 pages of text. Written like it possibly could've been used for an undergrad Intro. Geology course at UConn back in the day, but curiously the reading level is thoroughly general-interest geared and the interior layout like a coffee table book. Amazing find; I've never before laid eyes on any publication by any state agency that put such extreme care and production $$$ into presentation of such a niche topic.

Last edited:

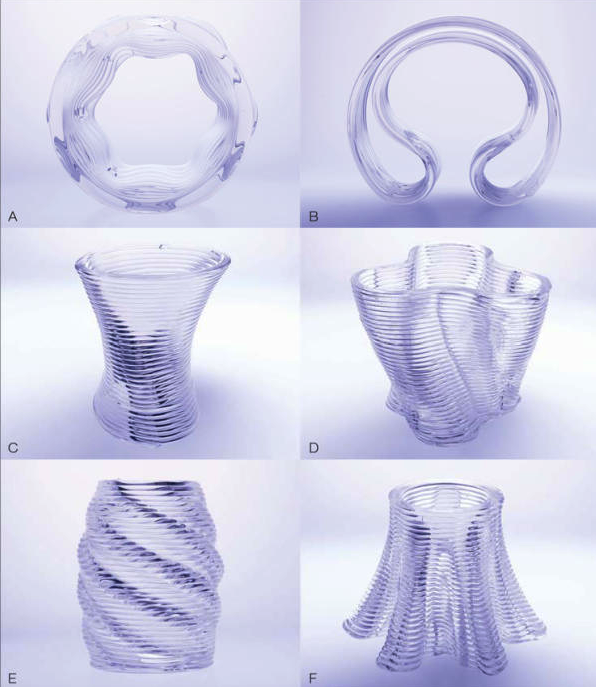

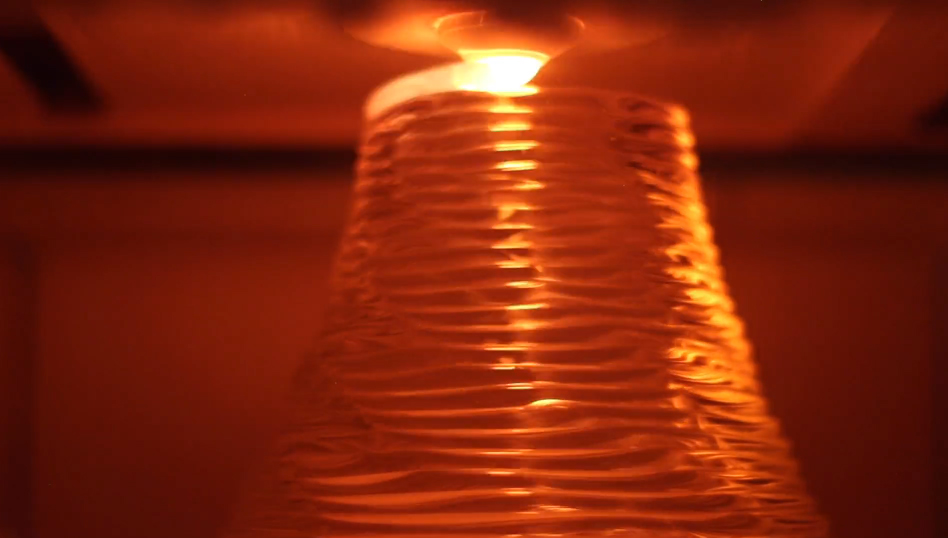

Lots of (very) new building materials being researched at MIT/Mediated Matter Group by Neri Oxman. As it's work out of the Media Lab, it's all mostly art installations/theoretical research, but these have some potential implications in Architecture moving forward.

3D Printed Glass

While glass isn't new, it is really hard to 3D print glass. The potential implications, with more research, are large in architecture/building applications.

Robotically fabricated chitosan, cellulose, pectin, and water

Naturally-occurring materials constructed in a new manner, could lead to new levels of sustainable buildings.

What the extent of these implications in architecture and the building/construction sector remain to be seen, but they are, at the very least, advancing sustainability and design to an extent, and raising questions pertaining to what we construct our buildings from. Not sure what's next for Mediated Matter Group, considering I believe Oxman moved to NYC permanently to set up a studio(?), but her students seemed to be thoroughly invested in continuing work in these realms.

Digital Structures, also out of MIT, is in the more applied/real-world realm of materials and structures. They have a lot of research on the feasibility and physics behind sustainable materials and building methods, mostly timber, but some low-carbon structure work too. They also have some work on robotic fabrication and construction, a rising field of interest in academia and at least part of the design and construction industry.

Steel and concrete are big targets for decreasing emissions in the building sector. Both account for 7-8% of global emissions each.

Boston Metal in Woburn, born out of MIT, backed by Bill Gates and a few other VC's, is working to decarbonize steel and eventually produce emission-free steel using Molten Oxide Electrolysis. They are looking to have a plant up and running in the next 4-5 years.

In concrete, there isn't much promising research to truly decrease emissions, apart from Solida Technologies out of NJ, which is changing the chemical processes involved in producing and curing concrete by using CO2. They promise it is higher performing, cures in 24 hours, and costs less, along with decreasing emissions substantially. I'm a bit weary, however, as they don't present any true/hard numbers on the strength they are getting with their mixes, one of the first things an engineer will ask about your mix.

3D Printed Glass

While glass isn't new, it is really hard to 3D print glass. The potential implications, with more research, are large in architecture/building applications.

Robotically fabricated chitosan, cellulose, pectin, and water

Naturally-occurring materials constructed in a new manner, could lead to new levels of sustainable buildings.

What the extent of these implications in architecture and the building/construction sector remain to be seen, but they are, at the very least, advancing sustainability and design to an extent, and raising questions pertaining to what we construct our buildings from. Not sure what's next for Mediated Matter Group, considering I believe Oxman moved to NYC permanently to set up a studio(?), but her students seemed to be thoroughly invested in continuing work in these realms.

Digital Structures, also out of MIT, is in the more applied/real-world realm of materials and structures. They have a lot of research on the feasibility and physics behind sustainable materials and building methods, mostly timber, but some low-carbon structure work too. They also have some work on robotic fabrication and construction, a rising field of interest in academia and at least part of the design and construction industry.

Steel and concrete are big targets for decreasing emissions in the building sector. Both account for 7-8% of global emissions each.

Boston Metal in Woburn, born out of MIT, backed by Bill Gates and a few other VC's, is working to decarbonize steel and eventually produce emission-free steel using Molten Oxide Electrolysis. They are looking to have a plant up and running in the next 4-5 years.

In concrete, there isn't much promising research to truly decrease emissions, apart from Solida Technologies out of NJ, which is changing the chemical processes involved in producing and curing concrete by using CO2. They promise it is higher performing, cures in 24 hours, and costs less, along with decreasing emissions substantially. I'm a bit weary, however, as they don't present any true/hard numbers on the strength they are getting with their mixes, one of the first things an engineer will ask about your mix.

Last edited:

- Joined

- Dec 10, 2011

- Messages

- 5,599

- Reaction score

- 2,717

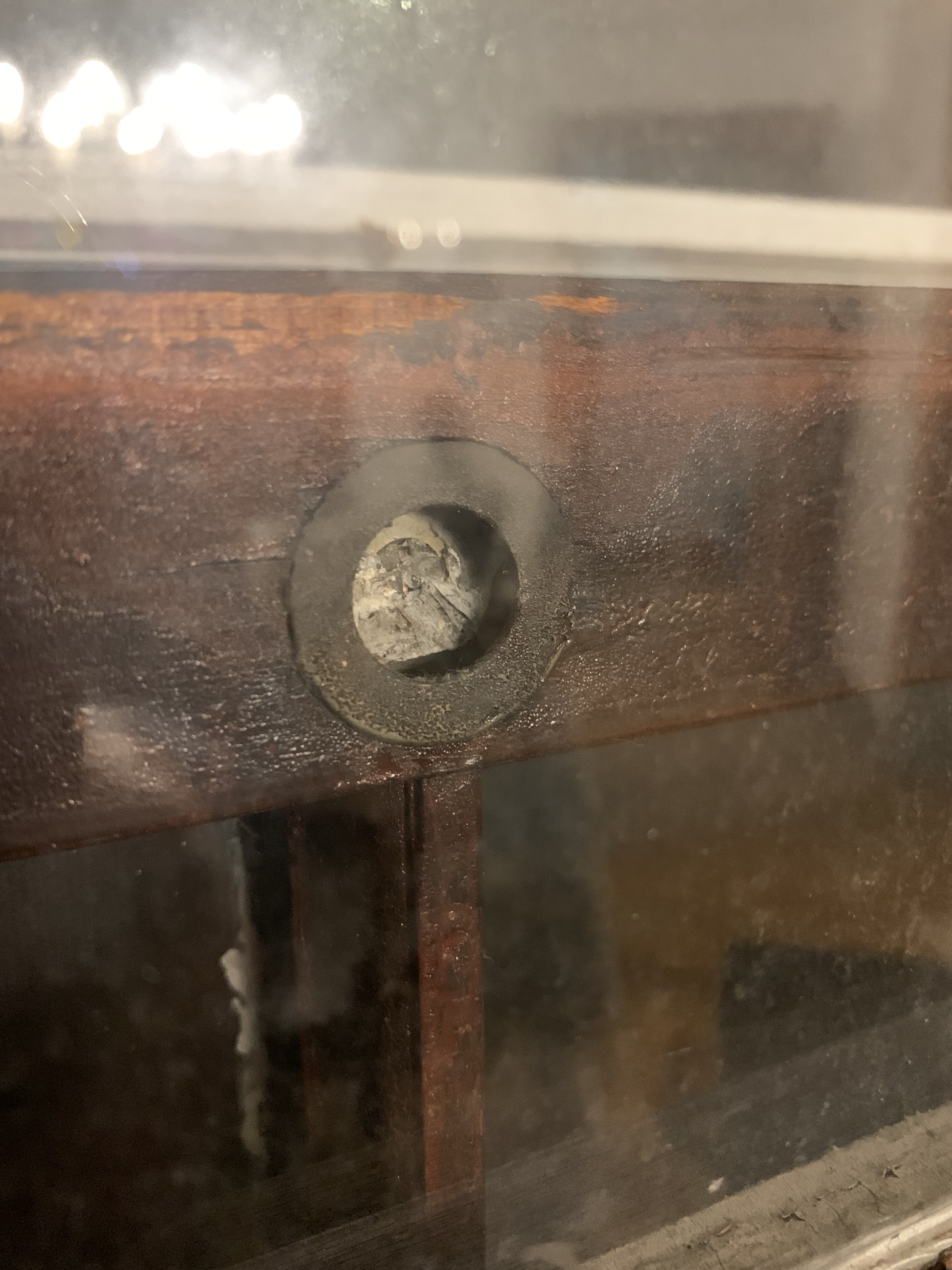

Why does this window from c.1890 (in a grand house in Melrose) have a slotted screw in a brass fitting, top center in the outer/upper sash?

The top of the sash is completely normal (no brass, no hardware, just evidence that the wood divider/mullion is joined in a square hole (the screw is not connected to something operating above it)

Other clue: while the changing the sash cord, the inner sash has a large easy access Panel for the counter weight, but none of the top sashes do.

It proved impossible to remove the top sash counterweight (nor to even touch the top of the counterweight) as one would need to for re-knotting the rope to the weight.

is it possible that the screw is some component of the counterweight system?

and to be clear, the counterweight pocket panel cover is 12”tall but the counterweight is something like 14” tall such that even with clever tilting there isn’t enough clearance to access where the rope tied to the outer sash counterweight—but they had to provide a method of changing the rope

The top of the sash is completely normal (no brass, no hardware, just evidence that the wood divider/mullion is joined in a square hole (the screw is not connected to something operating above it)

Other clue: while the changing the sash cord, the inner sash has a large easy access Panel for the counter weight, but none of the top sashes do.

It proved impossible to remove the top sash counterweight (nor to even touch the top of the counterweight) as one would need to for re-knotting the rope to the weight.

is it possible that the screw is some component of the counterweight system?

and to be clear, the counterweight pocket panel cover is 12”tall but the counterweight is something like 14” tall such that even with clever tilting there isn’t enough clearance to access where the rope tied to the outer sash counterweight—but they had to provide a method of changing the rope

Last edited:

- Joined

- Dec 10, 2011

- Messages

- 5,599

- Reaction score

- 2,717

From the GLX thread re: Old Lechmere

1) Asbestos was really at its peak from 1920 to 1960—a little late for Lechmere

2) Asbestos was used in electrical and heating systems (particularly insulating pipes) and interior tiles and wallboard—not particularly what Lechmeres “sheshelters were all about

3) To the extent there was asbestos it was probably concentrated in a few electrical/mechanical rooms that probably had lots of other remediation or recycling focus

Lead paint was probably used on every surface of every structure and was probably the bigger issue

What do people think of these 3 hypotheses:surprised there was no long-time asbestos remdiation.

1) Asbestos was really at its peak from 1920 to 1960—a little late for Lechmere

2) Asbestos was used in electrical and heating systems (particularly insulating pipes) and interior tiles and wallboard—not particularly what Lechmeres “sheshelters were all about

3) To the extent there was asbestos it was probably concentrated in a few electrical/mechanical rooms that probably had lots of other remediation or recycling focus

Lead paint was probably used on every surface of every structure and was probably the bigger issue

Last edited:

stick n move

Superstar

- Joined

- Oct 14, 2009

- Messages

- 12,148

- Reaction score

- 19,081

HUD Unveils New Report to Overcome Barriers to Offsite Construction

“WASHINGTON, DC– The U.S. Department of Housing and Urban Development, in partnership with the National Institute of Building Sciences and MOD X, has released the Offsite Construction for Housing: Research Roadmap, a strategic report that presents the key knowledge gaps and research needs to overcome the barriers and challenges to offsite construction.

High prices for buyers and renters are forcing Americans out of their homes and making housing unattainable. This crisis is to a large extent driven by supply constraints.

Offsite construction has the potential to deliver more affordable and accessible single and multifamily housing at scale. However, offsite construction for housing in the U.S. faces several challenges to increase uptake and adoption. This stands in considerable contrast to more mature international offsite construction industries, such as those in the UK, Japan, and Sweden.”

https://bostonrealestatetimes.com/h...to-overcome-barriers-to-offsite-construction/

“WASHINGTON, DC– The U.S. Department of Housing and Urban Development, in partnership with the National Institute of Building Sciences and MOD X, has released the Offsite Construction for Housing: Research Roadmap, a strategic report that presents the key knowledge gaps and research needs to overcome the barriers and challenges to offsite construction.

High prices for buyers and renters are forcing Americans out of their homes and making housing unattainable. This crisis is to a large extent driven by supply constraints.

Offsite construction has the potential to deliver more affordable and accessible single and multifamily housing at scale. However, offsite construction for housing in the U.S. faces several challenges to increase uptake and adoption. This stands in considerable contrast to more mature international offsite construction industries, such as those in the UK, Japan, and Sweden.”

https://bostonrealestatetimes.com/h...to-overcome-barriers-to-offsite-construction/