I just received a recent update from the project -- here are some highlights with quotes from Vladimir Bulović, the project’s faculty lead — and the Fariborz Maseeh Professor in Emerging Technology and associate dean for innovation in the School of Engineering from an earlier report:

http://newsoffice.mit.edu/2014/how-construction-mit-newest-building-will-affect-campus-0512

Construction of the MIT.nano building will itself pose many challenges, in the short term:

Just digging the hole for the new building’s foundation will involve removing 1.4 million cubic feet of dirt

The building itself will use 12,000 cubic yards of concrete, 3.4 million pounds of steel, and 53,000 square feet of glass.

On its way to the Building 12 site, all of that material will have to pass through just three access points.

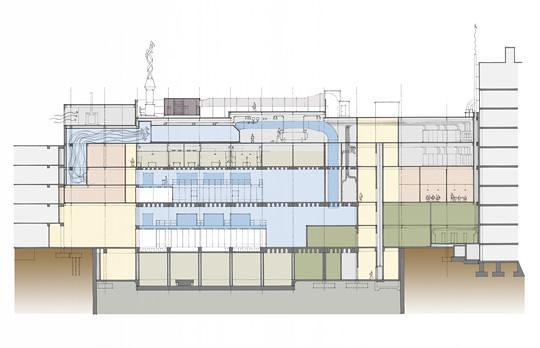

While traditional construction of such a building would use sheet pilings around the foundation, this project will instead use slurry walls, poured in place. This is expected to produce far less noise and vibration than the driving of sheet pilings.

Construction vehicles will use exhaust scrubbing to minimize the impact of fumes on adjacent buildings.

The building itself will be constructed with far more steel and less concrete than is typical for such a structure, greatly reducing the number of trucks needed to deliver materials to the construction site.

The demolition of the existing Building 12 — not expected to begin until 2015 — equipment will dismantle and crush sections of the building as they are removed “to minimize the crashing of large pieces,”

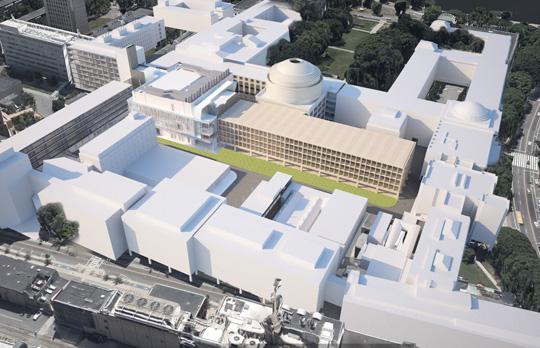

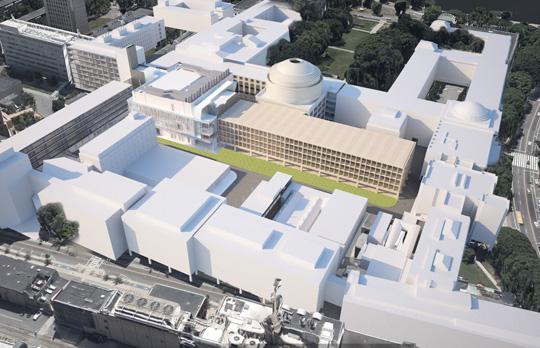

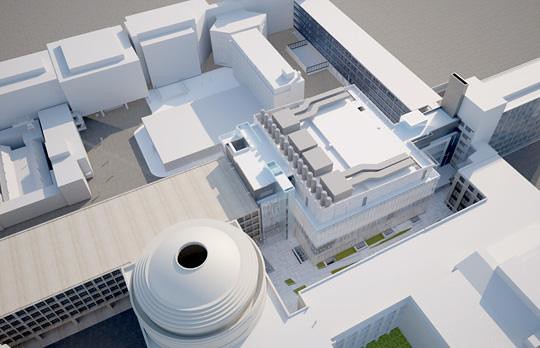

The new building, described by architect Samir Srouji of Wilson Architects as “a stone box wrapped around with a veil of glass,” will connect to Building 13, Building 16, and have easy ground-level access from the Infinite Corridor and Building 24.

MIT.nano and the courtyard looking northeast from Building 4.

Courtesy of Wilson Architects

When asked about the $350 million cost of the building, Bulović said that the cost is comparable, per square foot, to that of similar recent buildings at Harvard University and the University of Massachusetts at Lowell. He added that the cleanroom space within MIT.nano is larger than that found at those facilities, and that the new building will include the highest-quality vibration-free space for imaging equipment on the entire MIT campus.

Details of the layout and landscaping of spaces between MIT.nano and other buildings are still being worked out, Bulović said, but MIT sees a significant opportunity to animate these as community spaces, he added.

Current tasks for next 2 weeks mostly involve underground pipes and ducts:

1 Bldg. 3 Temp. MEPFP for construction trailers in main lot (see plan) Interior n/a

2 Bldg. 4 level 4 install vacuum piping & existing roof re-work (see plan) Interior n/a

3 Bldg. 10 Basement removal of existing FP Main (see plan) Interior n/a

4 Bldg. 12 Interior demolition / test pits (see plan) Interior n/a

5 Bldg. 13 Basement / Level 1 electrical install (see plan) Interior n/a

6 Bldg. 16 install temp. CHW & medium voltage feed (see plan) Interior n/a

7 Bldg. 26 Areaway install temp. CHW (see plan) Interior n/a

8 Install new 26 way elec. Duct bank, 16" CHW main, temp. 13.8 elec. Feed (see plan) Exterior A

9 SS prep for MH installation / prep for 10" FP main installation (see plan) Exterior B

10 Excavation and installation SOE for new CHW and FP mains (See plan) Exterior C

11 Pre-Trench for process pipe install / backfill / asphalt patch pre-trench (see plan) Exterior E

12 Pre-Trench for process pipe / excavate, install 16" CHW loop connection (see plan) Exterior F

13 Installation of 8" FP main in Presidents Courtyard (see plan) Exterior H

14 Construction trailers in Main Lot - Install temp. utility infrastructure (see plan) Exterior I

Note the location and task codes refer to a project-related map and proj management table [not included]